What materials and finishes are used for custom badges?

All Smith & Warren badges are made from solid brass — a time-tested metal that provides the ideal balance of weight, durability, and fine detail. Brass offers a professional feel without being too heavy or too light, and it’s well-suited for custom engraving and 3D elements.

Finish Options

Finish options affect the badge’s final appearance — including its color, shine, and level of protection. We offer a range of standard and deluxe finishes, each with its own characteristics and included enamel type.

We offer two main categories:

- Standard Finishes: Nickel, Gold, Rhodium – includes soft enamel lettering

- Deluxe Finishes: Two‑Tone, Sil‑Ray™, Gol‑Ray™, Côte D’Or – includes hard enamel lettering

Standard Finishes (Includes Soft Enamel)

|

Nickel Electroplate A cool-toned silver finish with a subtle blue undertone. Clean, professional, and our most popular silver-tone option. |

|

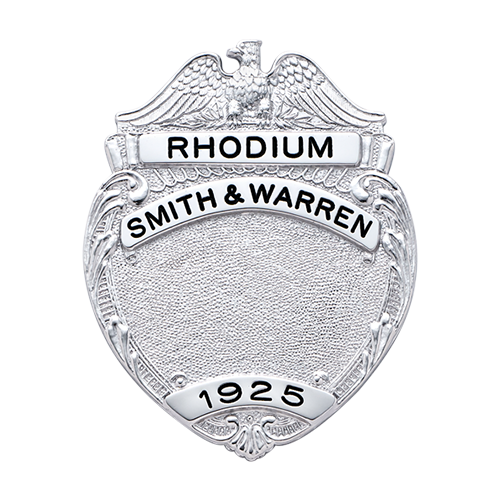

Rhodium Electroplate A brighter, whiter silver finish that resists tarnishing. Ideal for high-humidity environments or long-term wear. |

|

Gold Electroplate Traditional 24K gold finish. Most economical gold-tone option, with a warm, rich tone that may gradually fade with wear. |

Deluxe Finishes (Includes Hard Enamel)

Deluxe finishes include a protective clear coat and hard enamel lettering, offering smoother surfaces, deeper shine, and superior durability.

|

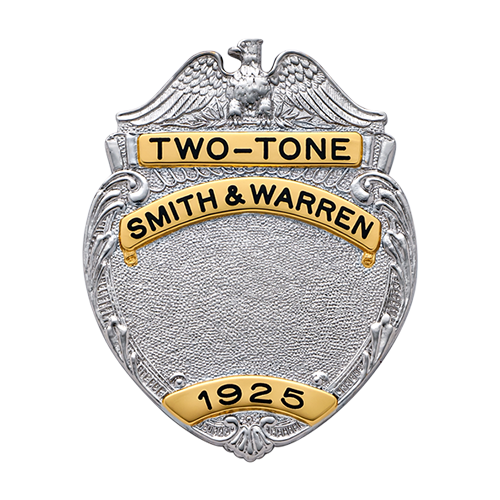

Two-Tone Combines gold and silver tones (usually Gol-Ray™ and Sil-Ray™) for a visually striking contrast. Commonly used to signify rank or distinction. |

|

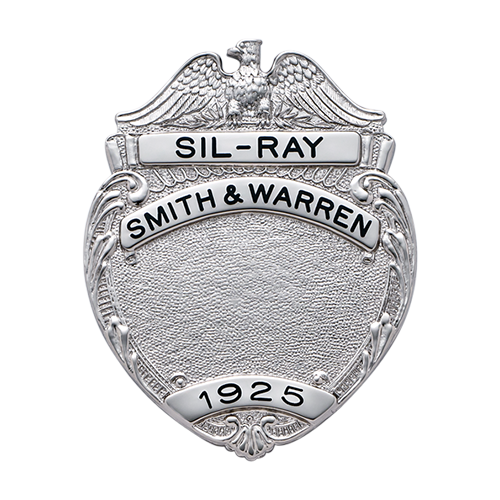

Sil‑Ray™ A premium silver-tone finish with a clear protective coat. Brighter than nickel and built to resist tarnish and wear. |

|

Gol‑Ray™ A premium gold finish with added layers of plating and a durable protective coating. Ideal for everyday wear, including badges carried in wallets. |

|

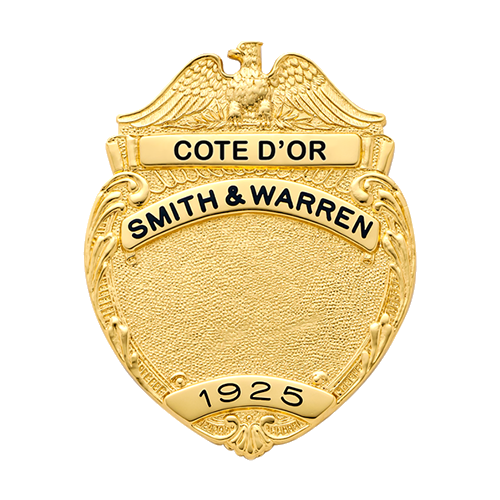

Côte D’Or™ Our brightest gold-tone finish, intended for presentation or display. Lacks a clear coat to preserve its maximum shine — not recommended for wallets or heavy daily use. |

Enamel Types: Soft vs. Hard

The finish you choose determines the type of enamel lettering applied:

- Soft Enamel – Slightly recessed into the lettering area. Common on standard finishes. May show fine grooves where color meets metal.

- Hard Enamel – Polished flush with the metal surface. Smooth, glossy, and more resistant to scratching or wear.

To explore color options and examples, visit our Enamel Types FAQ.

Choosing Your Finish

Gold-Tone Options

|

Silver-Tone Options

|

Still unsure? Contact us and our team will guide you to the best finish for your badge and how you plan to wear it.

For a detailed look at the process Smith & Warren uses to apply a precious metal finish to your custom badge badge, please click here

We are often asked about the difference between silver finishes Nickel Electroplate and Rhodium Electroplate. Check out this video to learn more.