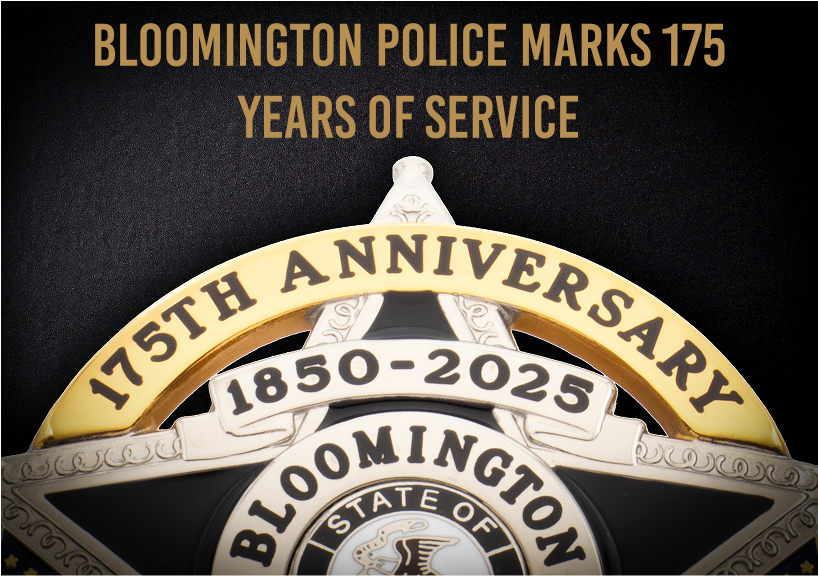

Bloomington Police Marks 175 Years of Service

The Bloomington Police Department is celebrating its 175th anniversary in 2025. As part of the celebration, the department wanted a special badge that reflected its proud history while offering a fresh, modern look.